Fire Sprinkler Pipe Fittings Black Malleable Iron Fire Fighting Pipe Fittings

Durable series of pipe fittings

Leyon is always focusing on research and development of malleable iron fittings, grooved fittings,tubing and valves that are mainly applied in such industries as fire protection, water supply, construction industry, municipal engineering and petrochemical.

They are designed for fire protection, gas supply and water supply even in other difficult areas to access.

Our series of pipe fittings are designed for fire protection, gas supply and water supply even in other difficult areas to access.

Production and packaging process

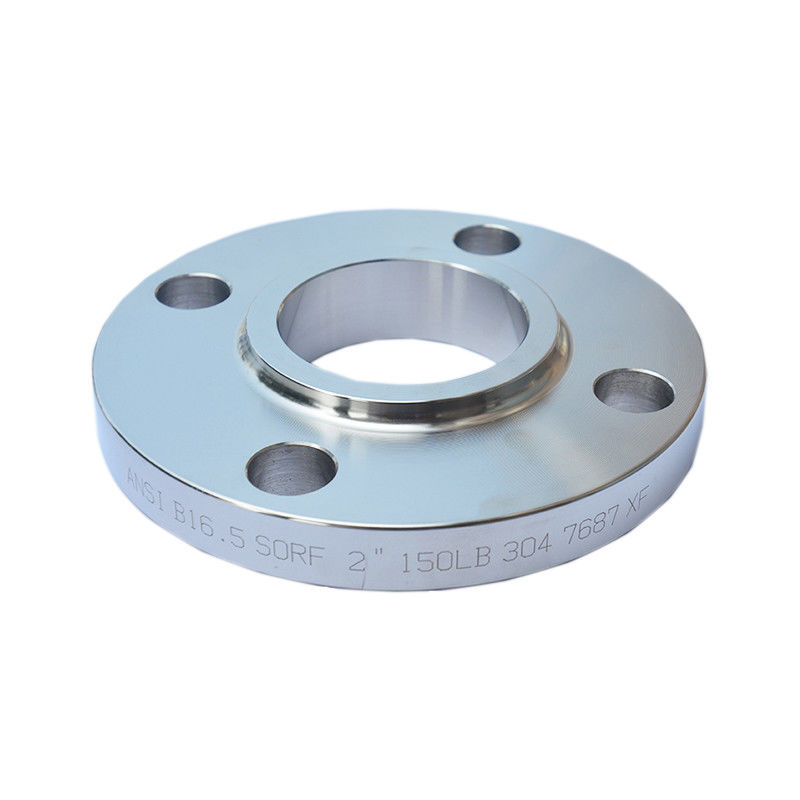

Steps: The melting-casing- MAO embryo-Polishing-Galvanized-Threading-Detection-Packaging

Blast-furnace smelting +electric furnace adjustment duplex smelting technology, 72 hours-3 sections-electric annealing technology, comprehensively ensure our products’ quality to be the best.

Take”six check +two inspect+one examine” measures, using Germany made FOUNDRY-MASTER Xline to check each pack of liquid iron’s chemical composition, ensure low defect rate and stable product quality.

Carefully choose multiple vendors, using Shanghai-made 99.99 high purity zinc, remove all the impurities which is bad product quality control, brighter surface, more fine zinc coat, better protective properties.

Small packaging numbers, which is easier for handle; carefully choose high quality non-recycled plastic made double-woven bag, make the product to be more break-resistant, no need worry about broken bag during handing process.

FM/UL Certification

UL certification and FM certification are quite authoritative certifications for product technical standards and product quality requirements, and their certification bodies are located in the United States. UL certification is a certification related to safety identification, which originated from the Underwriters Laboratories in the United States. UL is the abbreviation of Underwrites Laboratories Inc. in the United States. It is one of the world’s large private organizations engaged in safety testing and appraisal. It is an independent third-party inspection organization and a non-profit, A professional organization that conducts public safety experiments. It includes product inspection and factory inspection; the compilation and issuance of materials and standards; product safety certification and operating safety certification.

Product advantage

1. We use excellent raw materials and have a strict quality inspection system, which includes leakage testing, providing metallurgical and processing control, using spectroscopy to determine material quality, chemical analysis of varieties to strictly control compliance, and using fine grained, high strength, non-porous iron to produce the final castings. Because high quality iron is the starting point of producing high quality pipe fittings.

2: precision thread machining, in line with precision standards, such as ASME, EU, BS, DIN, etc. Threads have a precise construction, so the length and straightness of the threads allow them to easily engage threaded tubes.

At the same time, our pipe fittings have good toughness, long service life, smooth surface without sand holes, and soaked with anti-rust oil to strengthen anti-rust.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!